![]()

Technical Tip

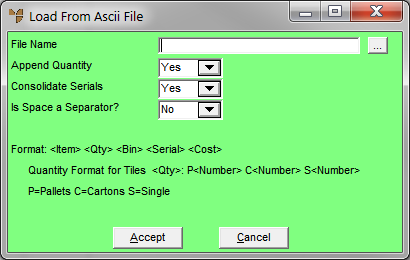

The file format for a stocktake file with serial numbers and stock units would look similar to this:

T001,10P,BULK,SER001

T001,2P,BULK,SER002

T001,5P,BULK,SER003

T001,10C,A001,SER001

T001,7C,A002,SER001

T001,20C,A003,SER002

T001,3C,A004,SER002

T001,7C,A002,SER003

T001,2C,A001,SER003

T001,12C,A002,SER003

T001,5S,B001,SER001

T001,7S,B003,SER002

T001,4S,B002,SER003